Sample Designs of Cattle Races and Corrals

Revised November 2023

Why does a curved chute and round crowd pen work better than a straight one?

- As the animals go around the curve, they think they are going back to

where they came from.

- The animals can not see people and other moving objects at the end of

the chute.

- It takes advantage of the natural circling behaviour of cattle and

sheep.

|

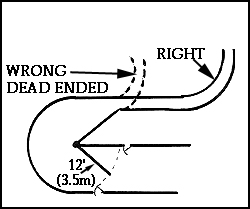

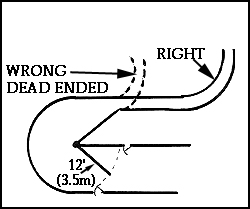

Right and wrong layout for Cattle. This diagram shows both the right and wrong layout for a curved race system. If the single file race is bent too sharply where it joins the crowd pen the cattle may refuse to enter because it looks like a dead end. Cattle standing in the round crowd pen must be able to see a minimum of three body lengths up the single file chute before the curve begins. |

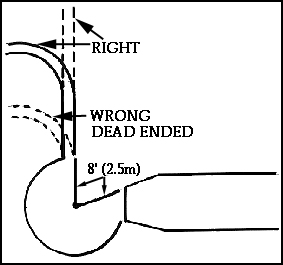

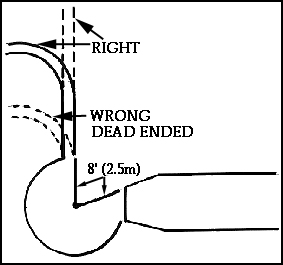

| Right and wrong layout for Pigs This diagram shows both the right and wrong layout for pigs. If the single file race is bent too sharply where it joins the crowd pen, the pigs may refuse to enter. The pigs must be able to see a minimum of three body lengths up the race before it bends. |

|

Design Recommendations

- The round crowd pen will work most efficiently if it is a full half circle, 180 degrees. A full half circle takes advantage of the natural tendency of cattle to go back to where they came from. For cattle, the crowd pen should have a 12 ft (3.5 m) radius. A shorter radius can be used for pigs and sheep.

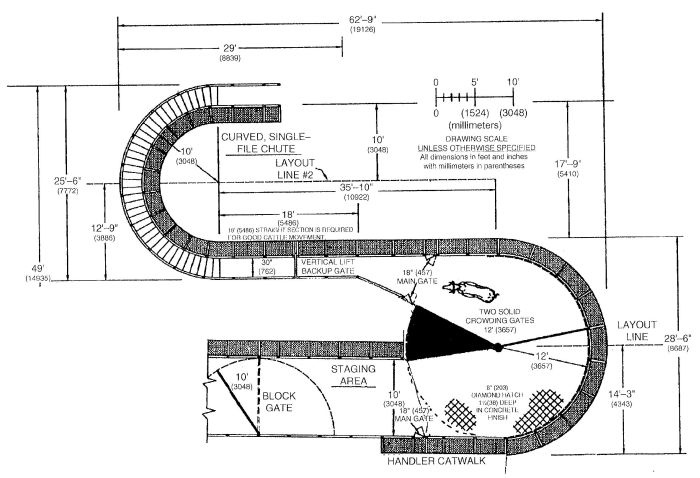

- A single file chute (race) will be very efficient if it has a single 180 degree or 90 degree curve. Multiple curves do not improve efficiency. The serpentine design with 2 180 degree curves should only be used in places where space is restricted. If there is sufficient space, a single 180 degree or 90 degree curve is recommended. It is a mistake to design many multiple curves into the single file race. Refer to drawings in the this website for more information.

- Never build a crowd pen on a ramp. If a ramp is required, it should be in the single file chute (race). Cattle and pigs will pile up if a crowd pen is built on a ramp.

- Install solid shields so that approaching animals do NOT see the people up ahead.

- Some breeds of beef cattle, such as Angus, have been bred to have wider bodies. For heavy weight, 1400-1600 lbs (635-680 kg), cattle widen a 30 inch (76 cm) wide straight sided chute to 32 inches (81 cm). N shaped chute shown in the older editions of Humane Livestock Handling will need to be widened for larger cattle. Cattle size has increased since the book was published in 2008. For large Holsteins, the pivot point of one way back stop gate may need to be raised. 6 to 8 inches (15 to 20 cm). A tall animal's back should never bump the pivot point.

Recommended lengths of single file races for cattle

| Facility Type |

Line Speed |

Minimum length |

Maximum length |

| Cattle Ranch and Properties |

N/A |

30 ft (9 m) |

75 ft (23 m) |

| Cattle Slaughter Plants |

Under 100/hour |

40 ft (12.2 m) |

75 ft (23 m) |

| Cattle Slaughter Plants |

100 to 400/hour |

80 ft (25 m) |

200 ft (60 m) |

Recommended lengths of single file races for pigs and sheep

If pigs are handled in groups in a gas stunning system, no race is needed.

Loose shackle systems where pigs can be batched on the bleed rail can operate efficiently with shorter races than systems that have to operate with a continuous flow.

Continuous flow systems with shackles attached to a chain conveyor for pigs or sheep:

- 0 to 100 animals per hour - 10 ft (3 m) to 25 ft (7.6 m)

- 100 or more animals per hour - 25 ft (7.6 m) to 50 ft (15 m)

Simple Economical Cattle Handling System Design

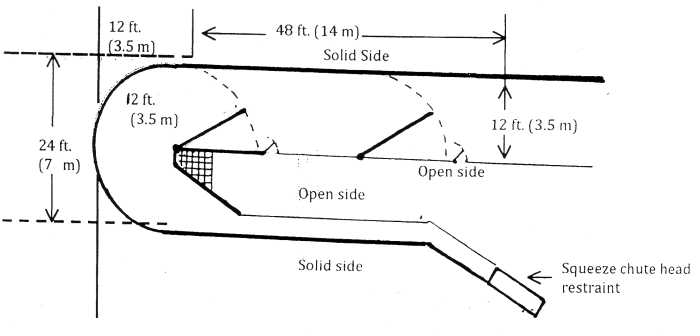

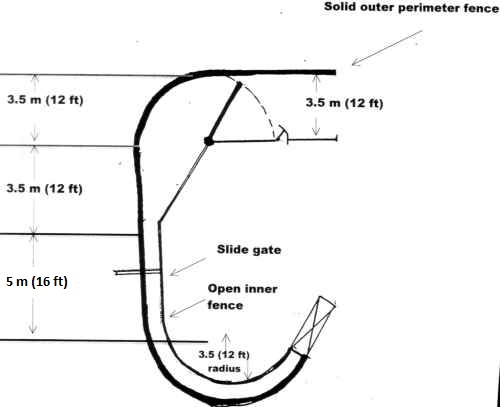

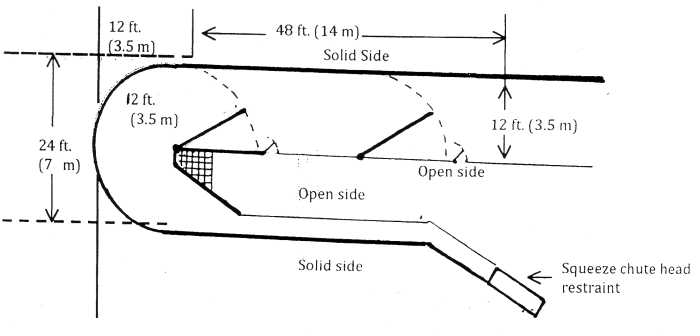

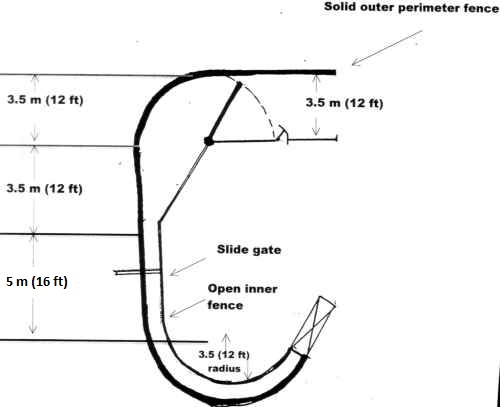

This compact design will fit in a small space and provide the advantages of a round crowd pen. The crowd pen is a full half circle to take advantage of the natural tendency of cattle to go back to where they came from. The outer fences are completely solid to block outside distractions. When a person with a flag stands on the small catwalk at the pivot point of the crowd gate, the cattle will circle around the person and enter the the single file chute. People who are operating the squeeze chute should work on the outer side of the squeeze chute. When the people are on the outer side, the slight bend in the single file chute will prevent incoming cattle from seeing the people who are operating the squeeze chute. To reduce costs, catwalks along the sides of the single file chute have been eliminated.

The inner fences are partially open so a person can work the flight zone while walking on the ground. The bottom portion should have a 4 ft (1.2 m ) high solid fence. This prevents the animal's feet from getting stuck in the fence. Since the cattle can see people through the partially open fence, people must stay out of this area. The handler should only enter this area when they need to move cattle into the squeeze chute. Another option with this design is to make all the fences completely solid and install catwalks. Catwalks must never be overhead. They must be located alongside the solid fence. The ideal height is to locate the catwalk so the top of the solid fence is at the waist height when a person stands on the catwalk.

More information and step by step instructions for building curved livestock handling facilities is in the book, Humane Livestock Handling, by Temple Grandin and Mark Deesing, published by Storey Publishing, North Adams, MA, USA.

Round crowd pen where the handler has the option of working at the pivot point of the crowd gate. The handler can stand in the black area and the cattle will circle around.

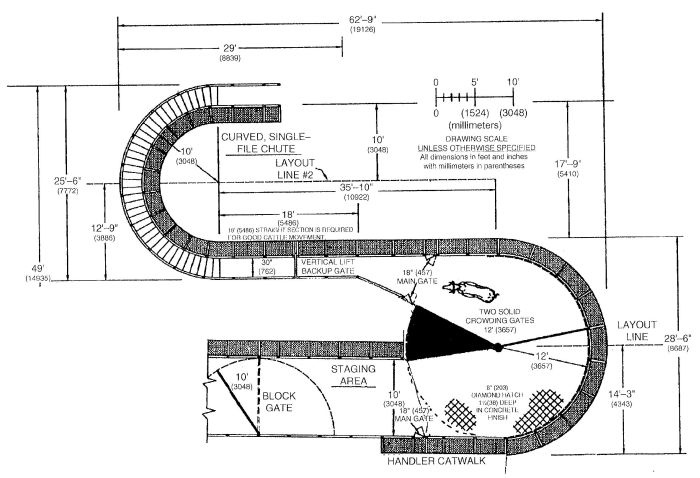

Curved Design with No Catwalks

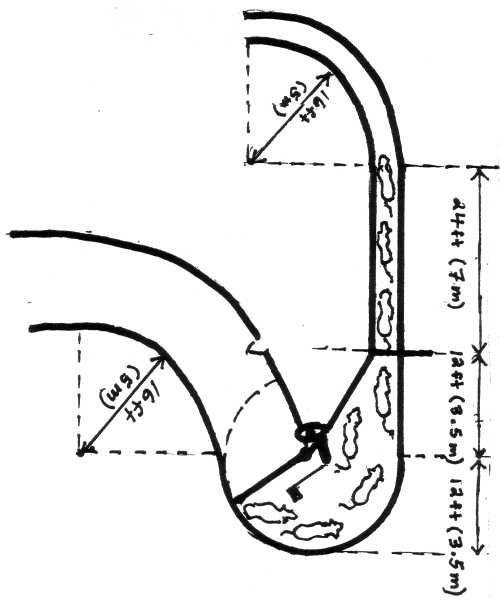

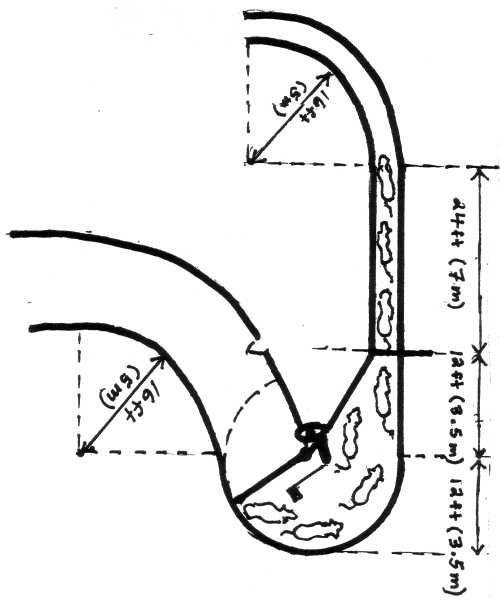

In this design, a skilled handler can work the flight zone and take advantage of the natural behavior of cattle to circle around them. The round crowd pen is worked from the ground at the pivot point of the crowd gate. The fences on the outer perimater are completely solid to block distractions. The inner fences are open on the top portion. A single handler can easily move cattle by working the point of balance. People MUST NOT constantly stand near the open side fence. This will cause the cattle to become agitated. This area is entered to move cattle and then people MUST back up and remove themselves form the animals's flight zone. If less skilled handlers will be using this design, the installation of an inner solid side and catwalk will facilitate cattle movement.

| Half Circle Tub and Race for One Person Operation The handler stands at the pivot point of the round tub and the cattle circle around. In this position, the bubble formed by the collective flight zone facilitates movement into the single file race. The design of the curved race enables the handler to always be positioned along the inner radius. The outer perimeter fences and round tub should have solid sides. Catwalks can be eliminated if top position of fences on the inner fences are open. This enables a skilled handler to work the flight zone. For less skilled handlers who do not understand flight zone principles completely, solid sides are recommended. |

|

|

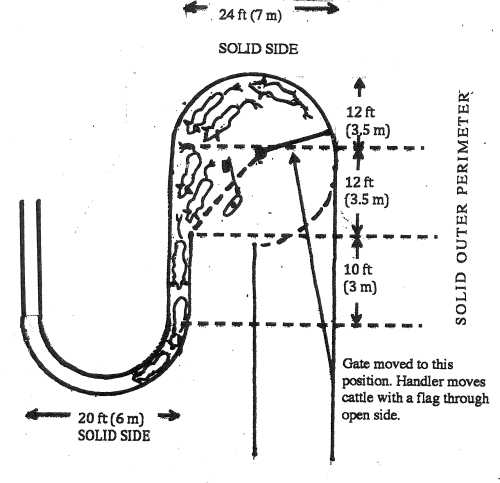

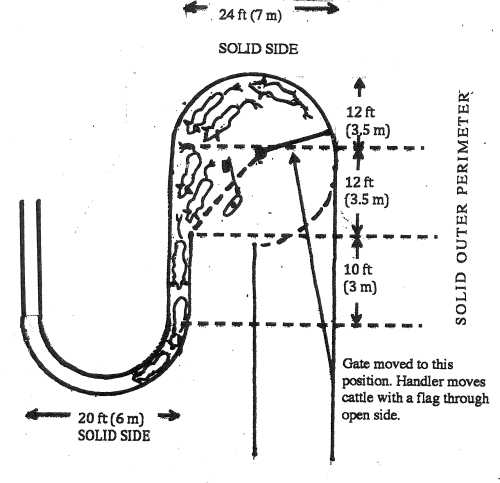

Round crowd pen where handler works at gate pivot point This design eliminates the catwalks on the outer perimeter of the round crowd pen. All outer perimeter fences are solid to block distractions. After the handler has filled the crowd pen and placed the gate in the position shown, he moves to the pivot point and moves the cattle with a flag through the open fence. The cattle will naturally circle around him because they have a natural behavior to go back to where they came from. The handler should take advantage of natural following behavior by waiting until the single file race has space in it before filling the crowd pen. This design works best with two people. One handler works the inner radius of the curved single file race. The second person brings in cattle from holding pens and moves them through the round crowd pen. |

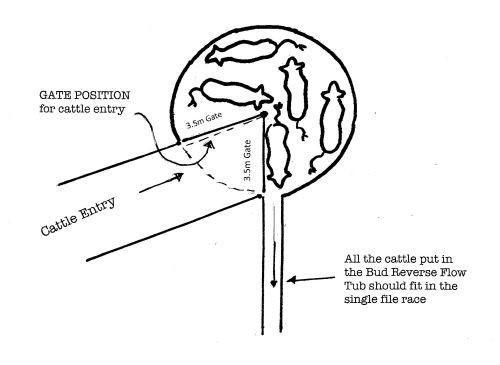

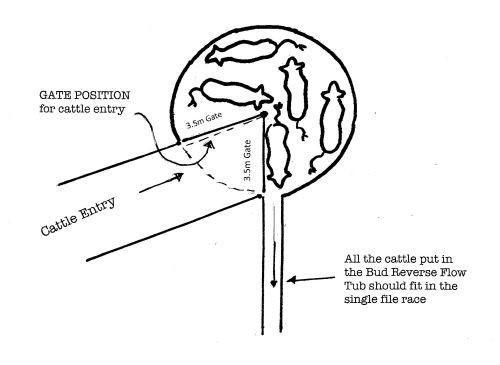

| Bud reverse flow tub This design combines some of the best features of a Bud Box and a conventional round tub system. The handlers are safe because they work outside the Bud Tub at the pivot point of the two gates. The dotted line shows the entry gate swing back in the correct position for cattle entry. The cattle enter the tub and then reverse and go back to where they came from. This facilitates entry into the single file race. This system will work most efficiently if the single file race is almost empty BEFORE the cattle are put in the tub. This enables the animals to immediately enter the single file race. Do not store cattle in the tub. To work effectively, it will require moving cattle in small groups. |

|

Temple Grandin yard demo at Beef Works (YouTube Video): Video showing handling in a chute with a solid outer fence and an open inner fence.

Temple Grandin yard demo at Beef Works (YouTube Video): Video showing handling in a chute with a solid outer fence and an open inner fence.

- Cattle Layouts

- Pig Layouts

- Cattle Layouts

- Buffalo (Bison) Layouts

- Pig Layouts

Click here to return to the Homepage for more information on animal behavior, welfare, and care.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.