New economical race and crowd pen designs

New economical race and crowd pen designs

New economical race and crowd pen designs

New economical race and crowd pen designs

and crowd pens. Handlers should be cautious about causing moving shadows. Cattle have a tendency to approach a more brightly illuminated area, provided the light is not glaring in their eyes. Lamps directed toward the interior of a truck will facilitate loading at night. However, squeeze chutes and loading ramps should not facing the sun because cattle will not approach blinding light.

Sometimes it is difficult to drive cattle under a roof or into a building for handling. The animals will enter more readily if they are lined up in single file in a race (Grandin, 1980a). When a squeeze chute is inside a building or under a shade, the single race should extend at least 3-5 m outside the shade. Never place the edge of the shade or a building wall at the junction between the single-file race and the crowd pen.

Cattle will also balk at moving or flapping objects. A coat flung over a fence or a shiny reflection off a truck bumper may stop the movement of cattle. If the cattle see people standing in front of the squeeze chute, they will refuse to approach. Installation of shields for handlers to stand behind may improve cattle movement. It will be easier to observe the distractions that are causing balking when the cattle are calm (Grandin, 1996). Problems with balking tend to come in bunches. When one animal balks, the tendency to balk spreads to the next animal in line. An animal must never be prodded until it has an opening to move into. Cattle can be easily moved in large pens with a piece of cloth or a plastic tied to a stick (Grandin, 1993a). The animals will move away from the rustling plastic or the flapping cloth. Dogs should only be used in open areas where there is sufficient space for the cattle to move away. When dogs bite livestock, it is highly stressful (Kilgour and DeLangen, 1970).

On steel corrals, it would be too expensive to construct all the holding pens, sorting pens and alleys with completely solid fences. On fences built from pipe or rod, a 30-60 cm-wide belly rail placed at cow eye height will facilitate movement and will prevent the ramming of the fence by excited cattle. This is especially important in facilities where wild Brahman, Brahman cross and Zebu cattle are handled because Brahman-type cattle are more excitable and difficult to block at gates (Tulloh, 1961). A belly rail is also recommended for handling excitable genetic lines of European continental cattle. Corrals constructed from wide wood planks do not need an additional belly rail because the boards create a substantial visual barrier.

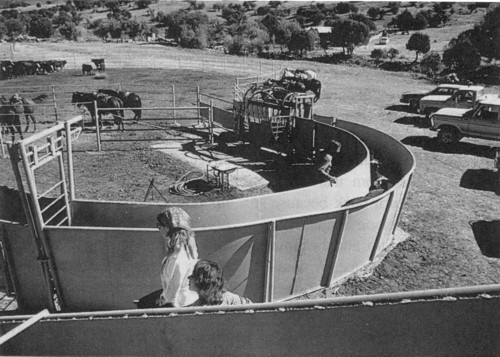

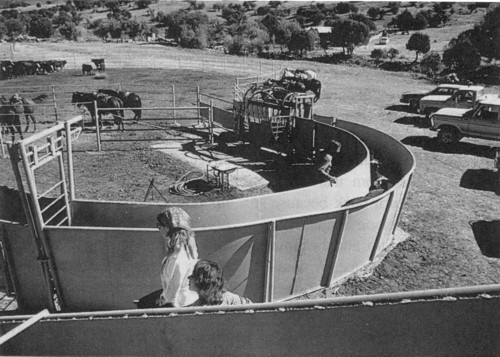

Fig. 1. Well-designed curved single-file race with solid sides and a walkway along the inner radius for the handler.

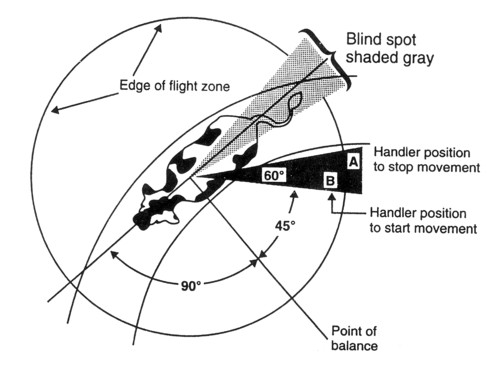

Fig. 2. Correct handler positions for driving cattle. The handler should remain on the boundary of the flight zone for most efficient cattle movement. He moves from position A to position B to make the animal move forward. From Grandin, 1980a.

The size of the flight zone varies depending on the tameness or wildness of the cattle. The flight zone for extensively raised cows may be as much as 50 m, whereas the flight zone of feedlot cattle may be 2-8 m. The edge of the flight zone can be determined by slowly walking up to the animals. The circle in Fig. 2 represents the edge of the flight zone. Extremely tame cattle are often difficult to drive because they no longer have a flight zone. The size of the enclosure in which the livestock are confined in may affect the size of the flight zone. Sheep experiments indicated that animals confined in a narrow alley had a smaller flight zone compared to animals confined in a wider alley (Hutson, 1982). Flight distance is also affected by previous experience. Cattle with previous experiences with gentle handling will have a smaller flight distance than cattle which have been handled roughly, and animals raised intensively in buildings in close contact with people will have a smaller flight distance than extensively raised range cattle.

Many people make the mistake of deeply invading the flight zone when cattle are being driven down an alley or into an enclosed area such as a crowd pen. If the cattle attempt to turn back, the person should back up and retreat from inside the flight zone. The cattle attempt to turn back because they are trying to escape from the person inside their flight zones. Cattle sometimes rear up and become agitated while waiting in a single-file race. A common cause of this problem is a person leaning over the race and deeply penetrating the flight zone (Grandin, 1983a). The animal will usually settle back down if the person backs up and retreats from the flight zone.

Cattle can be driven most efficiently if the handler is situated at a 45-60' angle to the animal's shoulder (Fig. 2). A well designed curved race has a walkway for the handler along the inner radius (Fig. 1). The handler is forced to stand in the correct position to facilitate animal movement. The curved lines on Fig. 2 represent the curved race. The solid fences in Fig. I block out all visual distractions except for the handler on the catwalk.

In Australia and South America, cattle are often given veterinary treatment in the single-file race, whereas in the US, Canada and many European countries, the animals are treated while held in a squeeze chute (crush) or head gate (stanchion) at the end of the race. In a South American or Australian operation, completely solid race sides would block access to the cattle. In this situation, the outer fence should be completely solid and the fence on the inside radius should be constructed from pipe or wood planks with spaces between them. The handler walkway is omitted. To prevent leg injuries, the inner radius fence should have a 60 cm high solid panel at the bottom. In curved race systems with completely solid sides, the handler walkway should run alongside the race and never be placed overhead. The distance from the walkway platform to the top of the race fence should be 100 cm.

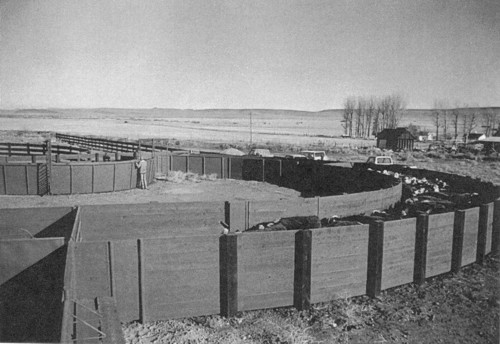

Curved races can be built from wood, steel or concrete. When wood or concrete is used, the race can be built in a series of straight sections (Fig. 3). The posts should be spaced 1.2 m apart. To reduce construction costs, the race in Fig. 3 has a single board for a person to step on to prod cattle. For large numbers of cattle, a complete handler walkway should be constructed.

Fig. 3. Curved wood, wide curved lane with solid sides which leads to the round forcing pen.

If space is restricted, a race with an inner radius as small as 1.5 m can be used if certain rules are followed (Grandin, 1984b). When the inner radius is shorter than 3 m, the race must have a minimum of a 3 m-long straight section joining the race to the crowd pen. This prevents the race from appearing to be a dead end. A race with a very short inner radius must be built in a continuous smooth curve. Cattle will get stuck if it is built in a series of straight sections. The recommended race width for a race with straight sides is 66-71 cm for adult cows and 51 cm for calves. These dimensions may vary depending on cow size. A V-shaped race should be 41-45 cm wide at the bottom and 81 cm wide at the 152 cm level. A common mistake is to make the race too wide. There should only be 2 cm of clearance on each side of the largest cow which will use the race. Fence height for races, crowd pens and corrals is 152 cm for English breeds and tame cattle, and 167-183 cm for Brahman, Brahman cross, Zebu excitable genetic lines of European continental or wild cattle.

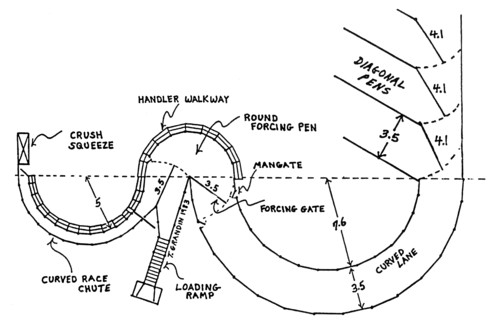

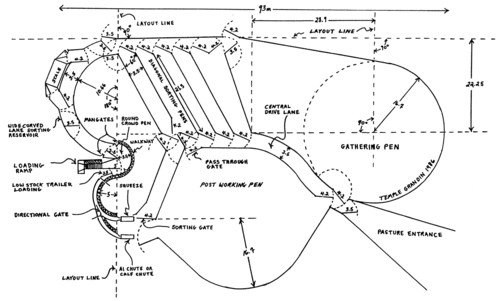

Fig. 4. Basic cattle handling system with curved race, round crowd pen and curved lane.

Fig. 4 illustrates a curved race, round crowd (forcing) pen and a wide curved lane. The crowd pen has solid fences and is equipped with a crowd gate which can be advanced behind the cattle. This gate should be solid. The wide curved lane holds cattle which are waiting to go into the crowd pen. A single person can easily move them into the crowd pen by working along the inner radius of the 3.5 m wide lane. This basic layout can be used on ranches, in feedlots for the main cattle handling facility, and in slaughter plants. For small handling facilities on farms or feedlot hospitals, the wide curved lane can be deleted and the round crowd pen can be connected directly to existing alleys. Fig. 4 is designed for easy layout. It consists of three half circles which are located along the dotted line on Fig. 4. If the crowd pen is constructed from wood, the fence can be built in a series of straight sections with 1.2 m post-spacing. The ideal length for the crowd gate is 3.5 m. A longer gate is unwieldy and a larger crowd pen is inefficient because it holds too many cattle. For smaller operations, the gate length can be reduced to 3 m.

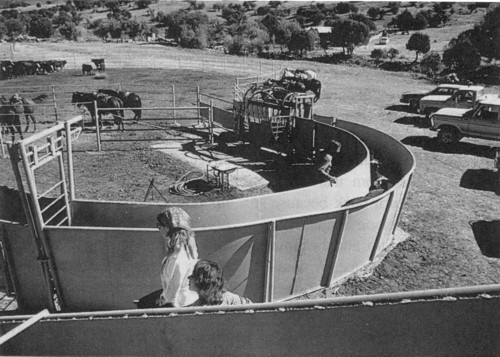

Fig. 5. Well-designed round crowd pen with solid fences and a solid crowd gate.

Fig. 5 illustrates a well designed round crowd pen with solid fences, solid crowd gate and a walkway for the handler. The handler can advance the crowd gate as he walks along the walkway. This crowd pen can be used to direct cattle into a single-file race or into a single-file loading ramp. There is one mistake in Fig. 5; the sliding gate at the junction between the single-file race and the crowd pen should be constructed from bars so that the cattle can see through it. A solid sliding gate makes the race entrance look like a dead end. Research indicates that solid fences for crowd pens are more efficient. Cattle moved faster through a crowd pen with solid fences compared to one with a pipe fence or partially open-board fence (Vowles et a]., 1984b). The inside of Fig. 5 is smooth to prevent bruises. All structural supports are on the outside.

If a straight crowd pen is used with a funnel leading to the single-file race, one side should be straight and the other side should be on a 30' angle (Meat and Livestock Commission, no date). If space permits, a round crowd pen is recommended because it is more efficient, as some types of cattle move more slowly when they walk straight through the crowd pen into the single-file race (Vowles et al., 1984b).

Mangates should be installed as indicated on Fig. 4, and they should be 45 cm wide because large cattle cannot pass through the narrow opening. A hinged solid metal or plywood flap which opens inward toward the cattle makes a good mangate. The flap is held shut with a spring and there is no latch. If a person is chased by the cattle, he can open the gate quickly because there is no latch.

Many animals are injured on loading ramps which are too steep. The maximum recommended angle is 20' for permanent ramps and 25' for adjustable ramps (Grandin, 1983b). The crowd pen on a single-file loading ramp must have a level floor except for a slight drainage slope. Sloping the floor of the crowd pen 10' will cause livestock to pile up against the crowd gate. On concrete ramps, stair steps are recommended. The dimensions for the stair steps are a 30-cm tread width and a 10-cm rise. The steps should be deeply grooved to provide a nonslip surface. On wooden ramps, the cleats should have 20 cm of space in between them (Mayes, 1978). To help prevent falling during unloading, permanently installed ramps should have a flat-level dock at the top (Stevens and Lyons, 1977). The minimum width for the level dock is 1.5 m. A self-aligning dock bumper will help prevent injuries caused by cattle stepping down between the truck and the loading-dock (Rider et al., 1974). Even if the truck backs up to the dock into a misaligned position, the gap is blocked by the self-aligning bumper. The bumper can be constructed from two pieces of steel welded together to form an 'L' shape. The 'L'-shaped piece of metal pivots on a heavy steel pin attached to the front of the dock. One side of the 'L' overlaps and rests on the dock floor. Loading ramps should also have telescoping side panels to prevent cattle from jumping out between the truck and the ramp. If a portable ramp is used, it should be sturdy. Ramps which sway or move when cattle walk on them are likely to cause balking.

Fig. 6. Corral layout for a large ranch where calves are shipped to a feedlot.

Fig. 7. Corral similar to Fig. 6 constructed from wood planks.

Groups of 20-40 animals are directed from the gathering pen into the curved sorting reservoir lane. This lane serves two functions. First, it holds cattle which are waiting to go to the loading ramp, or the squeeze chute, in the same manner which was described in Fig. 4. Secondly, it holds groups of cattle which are being sorted back into the diagonal pens (Fig. 6). Sorting back into the diagonal pens is efficient because the animals have a strong tendency to move back in the same direction from which they came (Grandin, 1980a). Many US ranchers prefer sorting back into the pens from an alley because it is quick, and it enables them to see the animals more easily than sorting through a single-file race. Cattle which have been sorted into the diagonal pens can either be released back to pasture or moved into the curved lane to go to the scale, loading ramp or squeeze chute.

When cows and calves are being separated, the calves are sorted into the diagonal pens. The cows are allowed to pass through one of the diagonal pens into the large postworking pen. This corral system can handle 300 cow-and-calf pairs or 400 adult cattle. To expand the systems, additional diagonal pens can be added. The length of the diagonal pens should not be increased. If they are too long, the cattle will bunch up. Increasing the size of the gathering pen is not recommended. If it is too big, driving cattle into the curved lane may be difficult. To increase the gathering area, an additional round gathering pen should be built at the pasture entrance. The corrals can be reduced for smaller herds by omitting one or two of the diagonal sorting pens and reducing the size of the gathering and post-working pens. The basic round shape of the pens should be maintained to eliminate comers for cattle to bunch up in.

Fig. 6 is equipped with a sorting gate in front of the squeeze chute. When cows are pregnancy-tested, the pregnant cows can be directed to the post-working pen, and the nonpregnant cows can be directed into one of the diagonal pens. A second sorting gate and alley can be easily added to create a three-way sort out of the squeeze chute. The sorting gate or gates in front of the squeeze chute can also be used for high-speed sorting as cattle walk through the squeeze. Any animal which needs veterinary treatment can be easily caught in the squeeze. An added advantage of sorting through the squeeze chute is that the cattle will learn to enter it readily. As an added incentive to enter the squeeze, feed can be made available in the postworking pen. Feeding palatable barley grain to sheep immediately after handling reduced the time required to drive them through a race (Hutson, 1985b).

This corral can also be used in pasture rotation systems which have centrally located handling facilities and the pastures are laid out like a wagon wheel (Savory, 1978). The gathering pen and post-working pen are eliminated and replaced with a 6 m-wide lane which encircles the corral and forms the hub of the wheel. Pasture fences radiate from the 6 m-wide lane. Switching cattle from pasture to pasture is easy when they come in for water in the 6 m-wide lane.

Fig. 6 can also be used in feedlots by eliminating the gathering and post-working pens and connecting the lanes to the alleys in the feedlot. Additional feedlot handling system layouts are available from Paine et a]. (no date). Paine's publication contains layouts of diagonal pens for shipping, receiving, weighing and loading cattle in large feedlots, and it also discusses feedlot hospital design.

The corrals in Figs. 6 and 7 are most suitable for use with British, European or British/European crosses with Brahman. These types of cattle can be readily sorted back into the diagonal pens by cutting animals out of the reservoir lane one at a time. Purebred Brahmans and Zebu tend to mill and circle more tightly. Cutting out animals and sorting them back is often more difficult.

Fig. 8 is designed for large properties (ranches) in Australia or South America which handle Brahman or Zebu cattle fattened on grass. In this type of operation, the steers remain on the ranch for several years instead of being shipped to a feedlot. More sorting is required due to the greater range of cattle ages and types. Older steers which have been sorted many times may be harder to sort back in an alley than inexperienced calves and yearlings, hence the Australians developed the pound yard (Dept. of Primary Industries, 1969). It enables the person sorting the cattle to look at each animal carefully before a sorting decision is made. However, it is slower than sorting back in the alley.

Fig. 8 provides the advantages of both high speed sorting in a single-file race and pound yard sorting. Cattle can be sorted three ways with the two sorting gates in the single-file race. During sorting, all cattle have to pass through the headgate and squeeze chute.

Fig. 8. Corral layout for a large Australian or South American ranch which has greater sorting requirements because steers remain on the ranch for fattening on grass. This design can also be used with electronic sorting and computerized systems, where each individual animal is evaluated and then sorted into different weight or frame size categories.

They can be sorted five ways out of the 5-m diameter pound yard. Each animal is admitted one at a time. A person on a platform over the pound yard can easily open and shut the gates with ropes or levers. A triangular block gate is used to stop incoming cattle and control cattle flow into the pound yard. It consists of 1.52 in high solid sided triangle with 76cm sides which is hinged at its apex. For details on building this gate, refer to Juergenson, 1979; Canada Plan Service, 1979. After sorting, the cattle in the sorting pens can be easily moved through the return lane for vaccinating, branding, truck loading, etc. If a dip vat is required, an additional directional gate and race can be added to lead to the dip vat. Fig. 8 is easy to set out and build by using the dotted lines as a guide. Fig. 4 has been incorporated into this corral. Sorting pens 2 through 6 are in a half circle with a 17.8-m radius. Fig. 8 can be easily modified for electronic sorting of cattle. Producers in the US are now doing more individual animal evaluation and there will be an increasing need for the type of layout shown in Fig. 8.

Choking in a headgate is usually asphyxiation caused by excessive pressure on the carotid arteries in the neck (White, 1961) or on the wind-pipe (Fowler, 1978). Due to the pressure on the arteries, animal can die very rapidly if it starts to lose consciousness in a headgate. The headgate must be released instantly when the first signs of asphyxiation occur. Choking is most likely to occur when a headgate is used without a squeeze. A properly adjusted squeeze chute can greatly reduce choking by preventing the animal from lying down. The best squeeze chutes have two movable side panels which are hinged at the bottom and pulled together by a lever system at the top. These are superior to chutes with a single movable side because the animal remains standing in a balanced position. The 'V' shape of the squeeze sides supports the animal. Proper adjustment of the space between the squeeze sides at the floor can greatly reduce choking. For 113-180 kg calves, the squeeze sides should be 16 cm apart at the chute floor, 21 cm for 272-360 kg cattle and 30 cm apart for most cows and fed steers (Grandin, 1980b). For large bulls the spacing may need to be wider.

On commercially available squeeze chutes, the sides have bars which can be dropped down for access to the sides of the animal (Fig. 9). The solid panel at the bottom can also be opened for access to the underside of the animal. When a squeeze chute is being purchased, the position of the control levers should be considered. On some headgates and squeeze chutes, the levers are situated where they may injure the operator if a latch is accidentally released. Commercially built headgates and squeeze chutes have two basic types of latches. The first type is a ratchet-latch which locks into a definite notch as the headgate or squeeze is closed. It has the disadvantage of being noisy, but it is safer because it is less likely to be released accidentally. The second type is a friction latch which consists of a steel rod which passes through a hinged metal plate. It has the advantage of being quieter than a ratchet latch, but it is more likely to come unlatched accidentally. Friction latches must be well maintained to keep them safe.

A survey conducted in large feedlots by Grandin (1980b) indicated that operator carelessness and trying to handle cattle too rapidly was the primary cause of choking, escaping and legs caught in squeeze chutes. The survey results also indicated that Brahman cross cattle were more likely to escape from a squeeze chute than English/European cross cattle. Allowing cattle to run rapidly into a squeeze chute and slam against the headgate can cause serious injuries. Examination of beef carcasses revealed old, healed spinal injuries in the back and neck (Grandin, 1980b). Even animals which appeared to be normal may have had hidden spinal damage. A skillful squeeze-chute operator can slow cattle down before they reach the headgate by partially closing the squeeze. Injuries can also be reduced by handling cattle quietly in the race leading up to the squeeze chute. Excessive use of electric prods especially on Brahman, Brahman cross and Zebu cattle can increase squeeze-chute injuries because excited cattle slam into the headgate and make greater attempts to escape.

To prevent shoulder bruises, the headgate should have neck bars constructed from round pipe with a minimum diameter of 6.2 cm. A 7.6 cm diameter pipe is recommended. The larger pipe diameter is less likely to bruise the neck. Headgates can be padded with old conveyor belts or split tires. Split motorcycle tires are the ideal size for headgate stanchions.

Many large feedlots and some ranches use hydraulics instead of muscle power to operate the squeeze chute. A correctly adjusted hydraulic squeeze chute is usually safer for both people and animals. The dangerous protruding levers are eliminated, and people are less likely to become tired and make errors which can cause an accident. Most commercially available hydraulic squeeze chutes in the US have a factory adjusted pressure relief valve which prevents excessive pressure from being applied to the animal. Cattle can be seriously injured if excessive squeeze pressure is applied. Animals which have been oversqueezed will sometimes appear to have pneumonia symptoms a few days later. Autopsies of cattle which have died from oversqueezing indicated that they had internal ruptures (Grandin, 1980b). When a hydraulic squeeze chute is designed, the force exerted on the animal should be determined. Measurements with a hydraulic load cell of the force exerted by the squeeze sides indicated that the recommended force 69 cm from the bottom pivots at a single point is 454-680 kg for cattle weighing over 272 kg and 270362 kg for cattle weighing less than 272 kg (Grandin, 1983a). These force readings are not hydraulic system pressure. Oversqueezing is most likely to occur if the pump motor supplied with the squeeze chute is substituted with a larger motor or if a tractor hydraulic system is used. If an animal has difficulty breathing while held in a hydraulic squeeze chute, the pressure relief valve should be loosened.

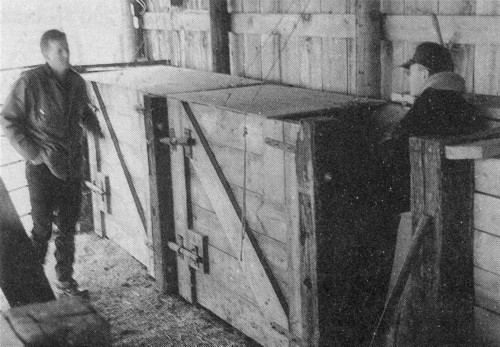

Fig. 10. Dark box chute for artificial insemination and pregnancy testing.

Cows can be easily restrained for artificial insemination or pregnancy testing in a dark-box chute (Parsons and Helphinstine, 1969; Swan, 1975; Canada Plan Service, 1984) Fig. 10. It has no headgate or squeeze sides and it will hold the wildest cow with minimum excitement. The dark box is 66-71 cm wide depending on cow size, and consists of completely solid sides, solid front, and a solid top. A piece of cloth is hung over the cow's rump to make it completely dark. When the cow is inside the box, she is in a snug dark enclosure. If the cows refuse to enter the dark box, a small window can be cut in the front gate. Cow entry is usually not a problem if a good single-file race leads up to the dark box. The dark box works on the same principle as the dark room which is used for handling deer in New Zealand. Groups of deer brought into the dark room will allow people to touch them and remain clam. Outside the dark room, the deer would become agitated and attempt to jump high fences. The dark box and the dark room may reduce physiological arousal levels (Hale et al., 1987; Lay et al., 1992). Experiments with poultry indicated that blind-folded birds had lower heartrates and respiration rates during shackling and slaughter (Douglas et al., 1984). Preliminary experiments with cattle are yielding a similar result (Kinsman, 1986, personal communication). A new novel dark box can cause stress (Lay et al., 1992). Prior to breeding cattle should be handled in the box so that they can become familiar with it.

If wild cows are to be handled, an extra-long dark box can be constructed. A tame cow which is not displaying estrus is placed in front of the cow which will be inseminated. A wild cow will usually stand quietly and place her head on the 'Pacifier' cow's rump. Cattle will often remain calmer when they are in bodily contact with other cattle (Ewbank, 1968). After insemination the cow is released through a side gate. The 'pacifier' cow remains in the dark box. If large numbers of cows are going to be pregnancy checked or inseminated, 26 dark-box chutes can be built side by side in a herringbone pattern on a 60' angle (McFarlane, 1976). They are built like regular dark-box chutes and the cows exit through the front of each chute. On some herringbone systems a single, large front gate is used to release all the cows at once. The outer fences, front gates, and tops are solid. The fences in between the cows are constructed from bars so the cows can see and feel each other. This will help keep them calmer.

Design ideas from equipment used in slaughter plants should be adopted for ranch and feedlot use (Marshall et al., 1963; Grandin, 1992, 1993b). A double rail conveyor restrainer used for beef cattle in slaughter plants outfitted with a head restraint device would almost eliminate injuries to cattle caused by lunging against the headgate. The animals straddle a moving conveyor. The system is described by Giger et al. (1977), Grandin 0987b, 1988, 1991, 1993c).

Fig. 11. Dip vat entrance design which will reduce injuries and chemical splashing. From Grandin, 1980a.

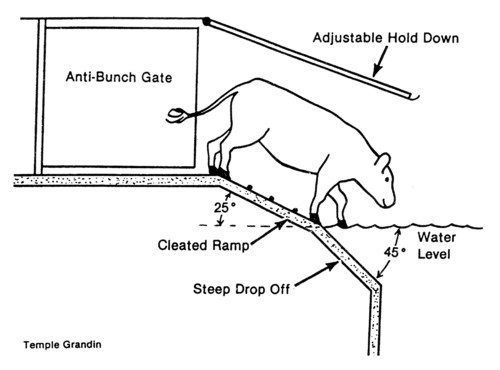

Injuries, stress and chemicals splashing on people can be reduced by a well designed entrance to the dip vat (Fig. 11, Grandin, 1980a). Many injuries and drownings occur because too many cattle enter the dip vat at once or they jump on top of each other. The two anti-bunch gates in Fig. 11 can be adjusted to allow only one animal to pass through at a time. The pair of gates is located on each side of the single-file race. The opening between the ends of the two gates is adjusted for animal size. To prevent wild cattle leaping into the vat, an overhead rack directs the animal head first into the water. Over 95% of the cattle will fully submerge their heads and will not have to be pushed under with a stick. The hold-down rack also reduces chemical splashing. To further reduce splashing, an 8 cm-diameter pipe should be installed on both sides of the vat wall approximately 1 m above the water. Splashing water will hit the pipe and fall back into the vat.

Each animal enters the vat by walking down a ramp which is deeply grooved to prevent the animal from slipping. The ramp is on a 20-25' angle. The animal can stand on the ramp without slipping. When it steps out over the steep drop off, its center of gravity will change and it will fall into the water. The animal will seldom attempt to back out because it does not start slipping. Many vat builders make the mistake of building a slide. A slide is a bad design because the cattle sometimes flip over backwards while going down the slide. More detailed information on vat design and construction can be found in Grandin (1980a,c, 1983a). For specific information on chemical use and disposal contact, it should be made with the local agricultural officials in each country. Universities and pharmaceutical companies can also provide information on dip vat management and chemical usage.

Animals can become crippled and injured if they slip and fall on slippery concrete floors. Cattle handling facilities should have nonslip floors (Stevens and Lyons, 1977; Grandin, 1983b). In races, crowd pens, scales and other cattle-handling areas, concrete floors should be deeply grooved. The grooves should be made in both directions in a 20 cm square or diamond pattern. The grooves should be 2.5-5 cm deep. In existing facilities, concrete floors can be roughened with a pneumatic hammer or a grooving machine. These recommendations are for handling facilities where cattle are handled intermittently such as auctions, feedlots and ranches. The deep grooves described above should not be used in the animal's living quarters or in milking parlors where dairy cows walk twice a day. The deep grooves will cause excessive hoof wear in these locations.

Brown, H., Elliston, N.G., McAskill, JW., Tonkins, L.V., 1981. The effect of restraining fat cattle prior to slaughter on the incidence and severity of injuries resulting in carcass bruises. Proc. West. Sec. Amer. Soc. Anim. Sci. 32, 363-365.

Campbell, W.C. et al., 1983. Ivermectin: a potent new antiparasitic agent.

Canada Plan Service, 1979. Triangular pivoting gate, Leaflet Plan S-108. In: Beef Cattle Housing and Equipment, Canada Plan Service, Agric. Eng. Services, Saskatchewan Dept. of Agriculture. Regina, Saskatchewan.

Canada Plan Service, 1984. Herringbone, A.I. Breeding chute, Plan 1819. Agriculture Canada. Ottowa, Ontario, Canada.

Dept. of Primary Industries, 1969. Basic plan for beef cattle yards. Advisory Leaflet No. 631, Division of Animal Industry, Australia.

Douglas, A.G., Darre, M.D., Kinsman, D.M., 1984. Sight restriction as a means of reducing stress during slaughter. Proc. 30th European Meeting of Meat Research Workers. Briston, England, September 9-14, 1984, pp. 10- 11.

Ewbank, R., 1968. The behavior of animals in restraint. In: Fox, M.W. (Ed.), Abnormal behavior in Animals. Saunders, Philadelphia, PA, pp. 159-178.

Fordyce, G., 1987. Weaner training. Queensland Agric. J, 113, 323-324.

Fowler, M.E., 1978. Restraint and handling of wild and domestic animals. Iowa State University Press, Ames, Iowa.

Giger, W., Prince, R.P., Westervelt, R.G., Kinsman, D.M., 1977. Equipment for low stress animal slaughter. Trans. Amer. Soc. Agric. Eng. 20, 571-578.

Grandin, T., 1980a. Observations of cattle behavior applied to the design of cattle handling facilities. Applied Anim. Ethology 6, 19-31.

Grandin, T., 1980b. Good cattle restraining equipment is essential. Vet. Med. and Small Anim. Clinician 75, 1291-1296.

Grandin, T., 1980c. Safe design and management of cattle dipping vats. Tech. Paper No. 80-5518. Amer. Soc. Agric. Eng. St. Joseph, Michigan.

Grandin, T., 1983a. Handling and processing feedlot cattle. In: Thompson, G.B., O'Mary, C.C. (Eds.), The Feedlot. Lea and Febiger, Philadelphia, pp. 213-235.

Grandin, T., 1983b. Welfare requirements of handling facilities. In: Baxter, S.H., Baxter, M.R., McCormack, J.A.C. (Eds.), Farm Animal Housing and Welfare. Martinus Nijhoff, Boston, pp.137-149.

Grandin, T., 1984a. Reduce stress of handling to improve productivity of livestock. Veterinary Medicine 79, 827-831.

Grandin, T., 1984b. Race system for cattle slaughter plants with a 1.5-cm radius curve. Applied Anim. behavior Sci. 13, 295299.

Grandin, T., 1987a. Animal handling. Veterinary Clinics of North America: Food Animal Practice 3 (2), 323-338.

Grandin, T., 1987b. Preventing squeeze-chute injuries. Large Animal Veterinarian, September-October, pp. 14-17.

Grandin, T., 1988. Double rail restrainer conveyor for livestock handling. Journal of Agricultural Engineering Research 41, 327-338.

Grandin, T., 1991. Double-rail restrainer for handling beef cattle. Paper No. 91-5004. American Society of Agricultural Engineers. St. Joseph, Missouri, USA.

Grandin, T., 1992. Observations of cattle restraint devices for stunning and slaughtering. Animal Welfare 1, 85-91.

Grandin, T., 1993a. Behavioral principles of cattle handling under extensive conditions. In: Grandin, T. (Ed.), Livestock Handling and Transport. CAB International, Wallingford, Oxon, UK, pp. 43-57.

Grandin, T., 1993b. The effect of previous experiences on livestock behavior during handling. Agri-Practice 14 (4), 15-20.

Grandin, T., 1993c. Handling and welfare in slaughter plants. In: Grandin, T. (Ed.), Livestock Handling and Transport. CAB International, Wallingford, Oxon, UK, pp. 289-311.

Grandin, T., 1996. Factors which impede animal movement in salter plants. J. Amer. Vet. Med. Soc. 209, 757-759.

Hale, R.H., Friend, T.H., Macauley, A.S., 1987. Effect of method of restraint on heart rate, cortisol and thyroid hormones. J. Anim. Sci. (Suppl. 1): (Abstract).

Hixon, D.L. et al., 1981. Reproductive hormone secretions and first service conception rate subsequent to ovulation control with Synchromate B. Therio. 16, 219-229. Hutson, G.D., 1982. Flight distance in Merino sheep. Animal Production 35, 231-235.

Hutson, G.D., 1985a. The influence of barley food rewards on sheep movement through a handling system. Applied Anim, behavior Sci. 14, 263273.

Hutson, G.D., 1985b. Sheep and cattle handling facilities. In: Moore, B.L., Chenoweth, P.J. (Eds.), Grazing Animal Welfare. Australian Veterinary Assn., Queensland, pp. 124-136.

Inglis, S., Williams, R., 1979. Cattle yards. Bulletin No. 3/79, Dept. of Agriculture, South Australia.

Juergenson, E.M., 1979. Handbook of Livestock Equipment. Interstate, Danville, Illinois.

Kelley, K.W. et al., 1981. Whole blood leukocytes vs. separated mononuclear cell blastogenesis in calves, time dependent changes after shipping. Canadian J. Comp. Med. 45, 249-258.

Kilgour, R., 1971. Animal handling in works, pertinent behavior studies. 13th Meat Industry Research Conference. Hamilton, New Zealand, pp. 9-12.

Kilgour, R., Dalton, C., 1984. Livestock behavior: a Practical Guide. Granada Publishing, Ltd., Frogmore, St. Albans, Herts, UK.

Kilgour, R., DeLangen, H., 1970. Stress in sheep resulting from management practices. Proc. New Zealand Soc. Anim. Production 30, 65-76.

Kilgour, R. et al., 1983. Using operant test results for decisions on cattle welfare. Proc. Conference on the Human Animal Bond. Minneapolis, MN, June 13-14, 1983.

Kinsman, D.M, 1986. University of Connecticut, Personal communication.

Lay, D.C., Friend, T.H., Grissom, K.K., Hale, R.L., Bowers, C.C., 1992. Novel breeding box has variable effect on heart rate and cortisol response of cattle. J. Anim. Sci. 35, 1-10.

Lemmon, W.B., Patterson, G.H., 1964. Depth perception in sheep: Effects of interrupting the mother-neonate bond. Science 145, 835-836.

Livestock Conservation Institute (no date). Only you can stop bruising. 239 Livestock Exchange Bldg., South St. Paul, MN.

Marshall, B.L., 1977. Bruising in cattle presented for slaughter. New Zealand Vet. J. 25, 83-86.

Marshall, M., Milbury, E.E., Shultz, E.W., 1963. Apparatus for holding cattle in position for humane slaughtering. U.S. Patent 3,092,871.

Mayes, H.F., 1978. Design criteria for livestock loading chutes. Tech. Paper No. 80-4023, Amer. Soc. Agric. Eng., St. Joseph, mi.

McFarlane, 1., 1976. Rationale in the design of housing and handling facilities. In: Ensminger, M.D. (Ed.), Beef Cattle Science Handbook. Agriservices Foundation, Clovis, CA 13, pp. 223-227.

Meat and Livestock Commission (no date). Cattle handling. Livestock Buildings Consultancy, Meat and Livestock Commission, Queensway, Bletchley, Milton Keynes, England. Midwest Plan Service, 1975. Beef Housing and Equipment Handbook, 3rd edn. Iowa State University, Ames, Iowa.

Paine, M., Teter, Guyer, P. (no date). Feedlot layout. Great Plains Beef Cattle Handbook, Bulletin GPE-5201 Agricultural Extension, Oklahoma State University, Stillwater, OK.

Parsons, R.A., Helphinstine, W.N., 1969. Rambo Al breeding chute for beef cattle. University of California Agricultural Extension Service, Davis, CA.

Prince, J.H., 1977. The eye and vision. In: Swenson, M.J. (Ed.), Dukes Physiology of Domestic Animals. Cornell University Press, New York, pp. 696-712.

Rider, A., Butchbaker, A.F., Harp, S., 1974. Beef working, sorting and loading facilities. Technical Paper No. 74-4523. Amer. Soc. Agric. Eng., St. Joseph, MI.

Savory, A., 1978. Ranch and range management using the short duration grazing method. In: Ensminger, M.E. (Ed.), Beef Cattle Science Handbook, Vol. 15. Agriservices Foundation, Clovis, CA, pp. 376-381.

Stermer, R.A., Camp, T.H., Stevens, D.G., 1981. Feeder cattle stress during handling and transportation. Technical Paper No. 81-6001. Amer. Soc. Agric. Eng., St. Joseph, MI.

Stevens, R.A., Lyons, D.J., 1977. Livestock bruising project: Stockyard and crate design. National Materials Handling Bureau, Dept. of Productivity, Australia (no city listed).

Stott, G.H. et al., 1975. Embryonic mortality. West. Dairy J., April, pp. 26-27.

Swan, R., 1975. About Al facilities. New Mexico Stockman, February, pp. 2425.

Tulloh, N.M., 1961. behavior of cattle in yards: 11. A study of temperament. Anim. Behav. 9, 25-30.

Vowles, W.J. 1980. A walk-through headbail for farmers to build. Agnote 1327/80. Victoria Dept. of Agriculture, Australia.

Vowles, W.J., Hollier, T.J., 1982. The influence of cattle yard design on the movement of animals. Proc. Aust. Soc. Anim. Prod. 14, 597.

Vowles, W.J., Eldridge, G.A., Hollier, T.J., 1984a. The behavior and movement of cattle through single file handling races. Proc. Soc. Anim. Prod. 15, 767.

Vowles, W.J., Eldridge, G.A., Hollier, T.J., 1984b. The behavior and movement of cattle through forcing yards. Proc. Aust. Soc. Anim. Prod. 15, 766.

White, J.B., 1961. Letter to the Editor. Vet. Rec. 73, 935.

Wythes, J.R., Shorthose, W.R., 1984. Marketing cattle: its effect on liveweight carcasses and meat quality. Australian Meat Research Committee Review, No. 46, A.M.R.C., Sydney.

Zavy, M.T., Juniewicz, P.E., Phillips, W.A., Von Tungeln, D.L., 1992. Effects of initial restraint, weaning and transport stress on baseline and ACTHstimulated cortisol responses in beef calves of different genotypes. Am. J. Vet. Res. 53, 551-557.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.