Center Track Conveyor Restrainer for Beef Cattle

Temple Grandin, Grandin Livestock Handling Systems Inc.

(Updated October 2022 with specifications for very wide cattle and modifications of the entrance)

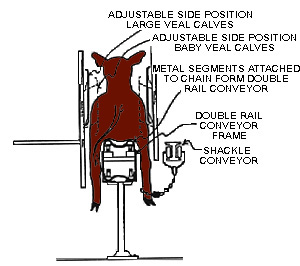

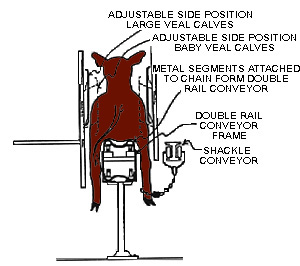

A double rail (center track) conveyor restrainer system designed by the author is based on research by Geiger et al. (1977) and it is adjustable for a wide variety of animal sizes. Baby calves, sheep and large 225 kg (500 lb.) calves can all be handled in the same restrainer. For adult cattle, a slightly wider conveyor is used. The width of the moving conveyor that the adult animals straddle is 30cm ( 12 inches).

Standard V restrainer conveyors may cause petechial haemorrhages during electric stunning (Thornton et al., 1979; Lambooy, 1986). There is a possibility that this system may reduce bloodsplash and speckle in electrically stunned animals (E. Lambooy, 1987, personal communication). With the double rail conveyor animals are supported under the brisket and belly while straddling the conveyor so that even large wild calves will ride quietly. The double rail requires less space than a V conveyor restrainer and it is compatible with existing shackling and bleeding systems.

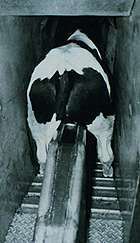

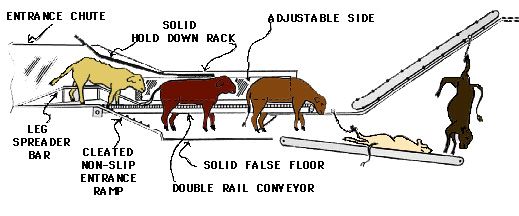

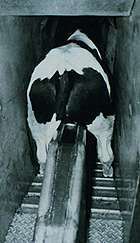

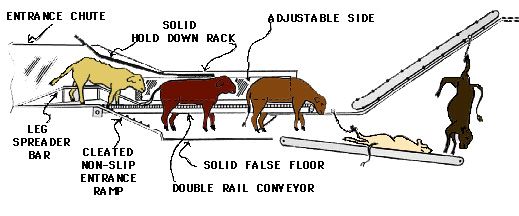

Proper design of the system is essential. The top of the conveyor is level with the floor of the entrance race. The animals walk down a cleated nonslip ramp which is on a 25 degree angle. The principle is that the animal will walk in quietly if it does not slip. A common mistake many people make is to remove the cleats. Making an animal slide down the ramp is wrong. A ramp with a shallower angle, such as 15 to 20 degrees, can be used. An entrance ramp steeper than 25 degrees must never be used.

|

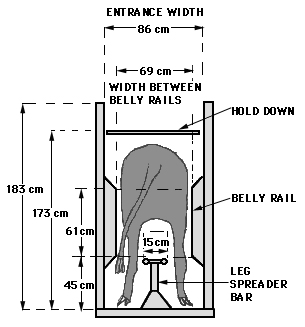

Veal calf entering the center track restrainer. For all species, it's very important to have a non-slip ramp with cleats. For adult cattle, a belly rail must be added (see diagram of cross section through the restrainer entrance). |

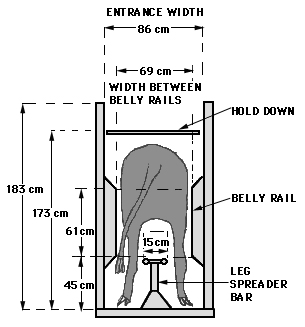

This same ramp design is also recommended for V conveyor restrainers. The sides of the ramp must be closed-in and animals must not see light coming up through the bottom of the restrainer. A stationary leg spreader bar over the ramp and in the first section of entrance race guides the animal's legs to the correct position. Calves entered this system with less balking compared to a V restrainer. The conveyor is constructed from metal segments attached to a moving chain. Each segment is bent to form the double rail configuration. Total width of the conveyor frame is 21.5 cm (8 1/2 inches). The moving segments are 19 cm (7 1/2 in.) wide with a 7.6 cm (3 in.) space in the middle to accommodate the animals' brisket. For adult cattle, a slightly wider conveyor is used. The width of the moving conveyor that the adult cattle straddle is 30cm ( 12 inches). The total inside width of the stationary sides is 107 cm (42 in) and the width of the entrance race which leads up to the conveyor is 86 cm (34 in). The width between the belly rails is 69 cm (27 in) (see diagram).

- To induce the cattle to stay still and ride quietly, the solid hold down rack MUST be long enough so that the animal entering the restrainer can NOT see out until it's feet are completely off the entrance ramp.

This system MUST have a solid false floor just below the animal's feet. Cattle will balk and refuse to enter if they see a steep drop off below the conveyor.

Adjustable sides accommodate different sized animals. The adjustable sides press lightly against the top portion of the animal's body. They are on pivots and the bottom edge of the adjustable side is slightly above the top of the conveyor. This provides room for the animal's leg joints. Pressure on the leg joints causes stress and discomfort. The pivot mechanism simultaneously adjusts the width between the sides and the leg joint space. For calves, the width between the adjustable sides can be varied from 51 cm (20 in.) to 25 cm (10 in.). The space between the bottom of the adjustable sides and the top of the double rail is 5 cm (2 in.) when the sides are spread 25 cm ( l0 in.) apart and 12.7 cm (5 in.) when the sides are spaced 45 cm (18 in.) apart.

| Full size double rail restrainer for adult cattle. Inner adjustable sides: The position of the adjustable sides in relation to the steer's body can be seen in the first picture on this page. The adjustable sides are on pivots like a parallelogram. For adult cattle, the inside width between the adjustable sides is 53 cm (21 in) for small cattle and 73 cm (29 in) for large cattle. |

|

June 2022 Update: Dimensions for large, wide, grain fed cattle

Cattle have become much larger in the last 10 years. They have been bred to be wider and produce more meat. The orginal dimensions shown in the article are for up to 680 kg (1500 lb) grain fed cattle that were produced 10 years ago. Today Angus cattle in the U.S. are heavier and wider. The entire system will need to be widened 15 cm (6 in). The conveyer remains the same dimensions. Use the dimensions below for wide grain fed cattle that are over 680 kg (1500 lb):

- Adjustable sides large cattle position: Change 73 cm to 88 cm

- Adjustable sides smaller cattle position: Change 53 cm to 68 cm

- Width between the belly rails: Change 69cm to 84 cm

The framework will also need to be widened. These widened dimensions should only be used for extremely large, wide cattle. Use the original dimensions for most other cattle.

Another very important design feature is the solid hold down rack and the solid false floor. To keep the animal calm, the hold down rack must be long enough to prevent the animal from seeing out until it's rear feet are off the entrance ramp. The solid false floor prevents the animal from seeing the "visible cliff" effect under the restrainer. This greatly reduces the amount of animals balking and refusing to enter.

The solid false floor is essential to facilitate cattle entry into the

restrainer.

|

|

Cross Section through restrainer entrance

before the animal reaches the conveyor |

Cross Section through the conveyor

and hold down |

These diagrams illustrate dimensions for adult cattle. Dimensions for calves are given in previous text. For adult cattle there must be a belly rail to keep the cattle centered as they enter the restrainer. The belly rail makes the animal straddle the leg spreader bar and it prevents the animal from walking on one side of the leg spreader. The belly rail must not extend all the way to the floor. The animal's feet need space for walking.

October 2022 Update: Modifications of the entrance of the center track conveyor restrainer

It is important for people to understand the principles of the entrance design. Remove the belly rails and keeping the outer entrance walls the same width is NOT recommended. The purpose of the two belly rails is to center the animal over the leg spreader bar. The original dimensions provided smaller cattle with lots of room so they could walk wasily on each side of the conveyor. For bigger cattle BOTH the width between the belly rails and the width between the entrance sides MUST be widened. The outer entrance sides MUST also be widened, to provide room for very large cattle to walk easily. The animal has to have sufficient space on each side of the leg spreader bar to move it's feet when it is entering.

Installing a spot light to illuminate the entrance to the restrainer will make animals enter more easily and reduce balking. Good lighting is essential. The cattle will not enter a dark tunnel.

Correcting Common Problems with Conveyor Restraints

Problem: Animal refuses to enter

Solutions:

- Add lighting. Cattle, pigs, or sheep will not enter a restrainer that looks like a dark tunnel.

October 2022 Update on lighting

LED lights have replaced many other types of lights in cattle handling facilities. There is a possibility that cattle may be able to flicker on some types of LED lights. This may have a negative effect on cattle movement. An easy way to determine which types of LED lights flicker is making a video with a phone set for slow motion. Make sure it is played back in slow motion. To ensure that it is actually played back in slow motion, have a person wave while taking the slow motion video.

- Block vision of moving people and equipment that an incoming animal can see through the restainer. Animals will not approach visible people.

- Make sure the false floor is in place. Animals will not enter if they can see the "visual cliff" effect. Install a solid false floor so it is 20 cm (8 in) below the hooves of the largest animals.

- The entrance ramp must be non-slip. Animals panic when they slip. Cattle will confidently walk down a non-slip entrance ramp. Never remove the cleats. It should work on the same principle as the non-slip dip vat ramp that was shown in the HBO move "Temple Grandin."

- Raise the solid hold down so incoming animals do not bump their shoulders. Animals will refuse to enter if they bump their backs on equipment.

Problem: Animals become agitated or vocal

Solutions:

- Remove sharp edges that may be gouging the animal. Very small sharp edges can be felt.

- The solid holddown rack must be long enough so that the animal is fully settled down and riding on the conveyor BEFORE it sees out. Experiment with pieces of cardboard to determine the best length.

- Move people who are standing in front of the restrainer. Incoming cattle should not see people.

- Reduce use of electric prods and eliminate people yelling and whistling. People should be quiet.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.

Click here to return to the Homepage for more information on animal behavior, welfare, and care.